Precision and Versatility in Toolroom Lathes: CTL-618EVS Overview #

The CTL-618EVS Toolroom Lathe is engineered for high-precision machining, offering a blend of robust construction, advanced features, and user-friendly operation. This article provides an in-depth overview of its capabilities, technical specifications, and the range of accessories available to enhance its performance in demanding toolroom environments.

Key Features #

- 280mm (11") swing over bed

- 457mm (18") distance between centers

- Dual range Inch/Metric quick change gearbox

- Infinitely variable spindle speeds from 50–4000 RPM

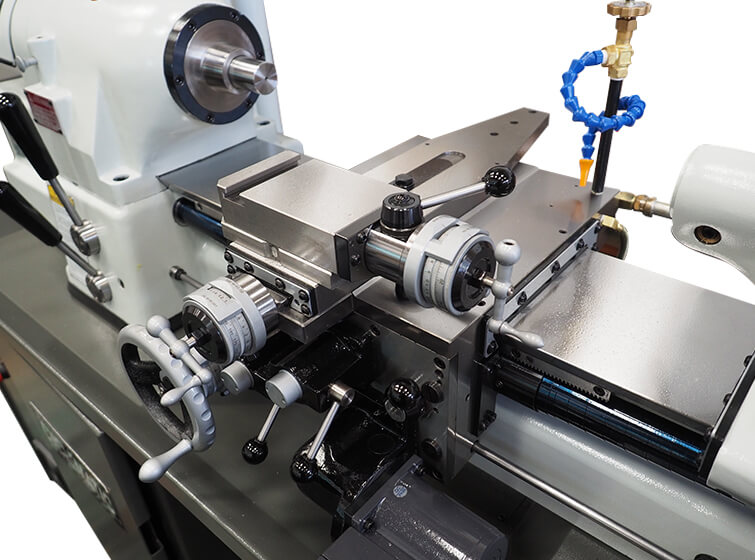

- Full bearing carriage with Turcite-B slideway bearing material

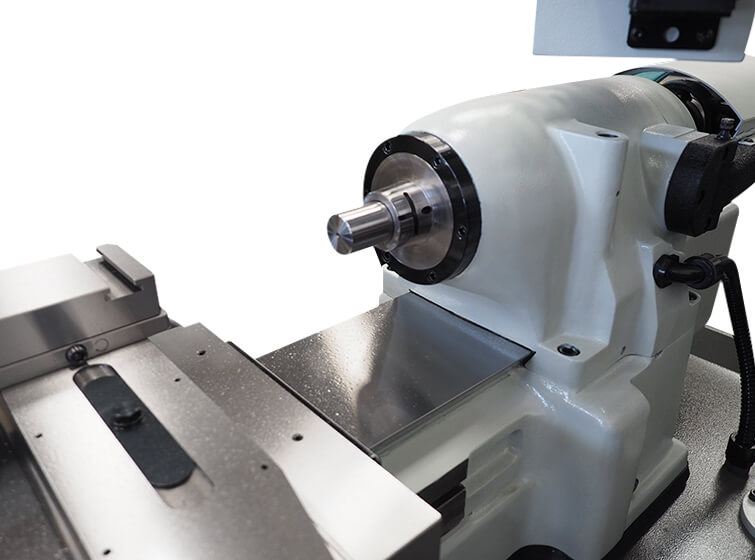

- Spindle mounted in high-precision preloaded angular contact ball bearings

- Fast lever collet chucking with single movement

- Independent infinitely variable feeds for accurate cuts and efficient chip removal

- Quick change gearbox for easy precision threading

- Automatic thread length control with fine adjustable stops

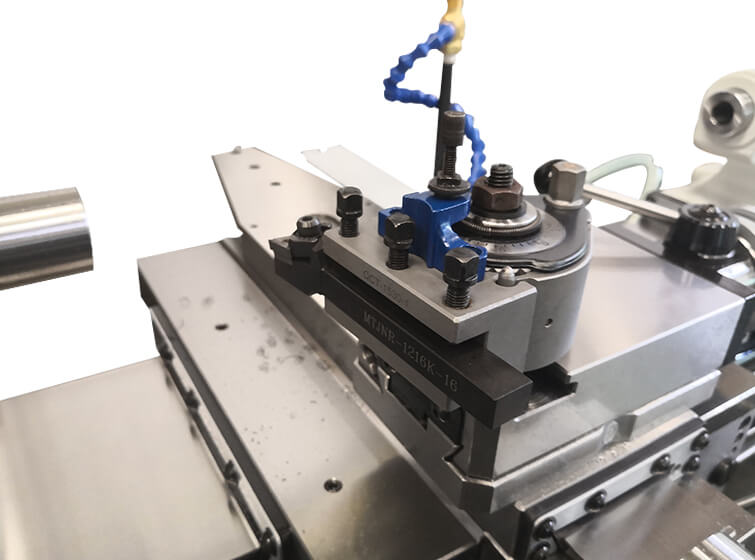

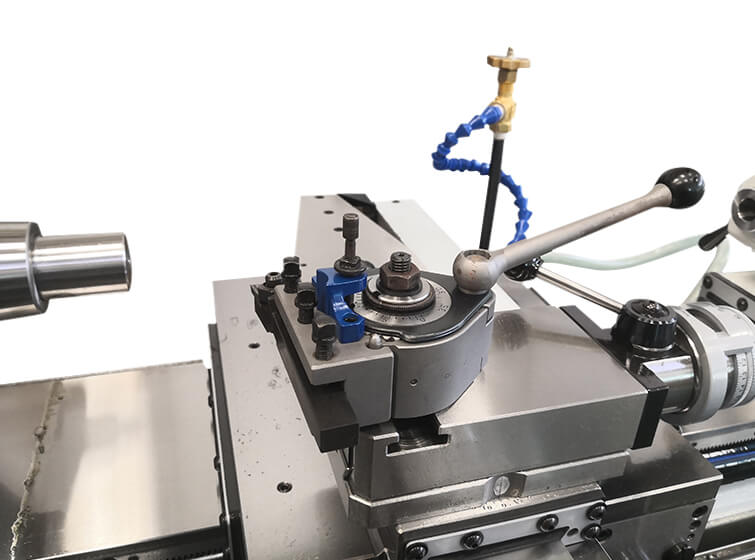

- Quick-action tool post slide for instant clearance during threading

- Hardened and ground alloy tool steel bed way with angular guide ways for chip management

Technical Specifications #

| Specification | Value |

|---|---|

| Spindle Capacity (with Chuck) | 150 mm (6") |

| Spindle Capacity (with Expanding Collets) | 76 mm (3") |

| Spindle Capacity (with Round 5C Collets) | 27 mm (1-1/16") |

| Spindle Capacity (with Hexagon 5C Collets) | 22 mm (7/8") |

| Spindle Capacity (with Square 5C Collets) | 19 mm (3/4") |

| Spindle Capacity (with Step Chucks) | 27–152 mm (1-1/16–6") |

| Spindle Nose Diameter | Ø55.5 mm (Ø2.189") |

| Spindle Nose I.D/O.D | 5C (10°) / 4° Taper |

| Spindle Speeds (Variable) | 50–4,000 rpm (5C) / 50–3,000 rpm (with 6" 3-jaw chuck) |

| Inverter Spindle Motor | 3 HP |

| Hole Through Spindle | 31.75 mm (1-1/4") |

| Bar Stock Diameter (5C collet) | Ø27 mm (Ø1-1/16") |

| Distance Between Centers | 457 mm (18") |

| Swing Over Bed | 280 mm (11") |

| Swing Over Carriage | 230 mm (9") |

| Swing Over Cross Slide | 152 mm (6") |

| Carriage Power Feed Range (Variable) | 8–178 mm (5/16"–7") |

| Cross Slide Power Feed Range (Variable) | 5–102 mm (3/16"–4") |

| Cross Slide Travel | 152 mm (6") |

| Quick-action Compound Slide Travel | 2.5 mm (0.1") |

| Compound Slide Travel | 76 mm (3") |

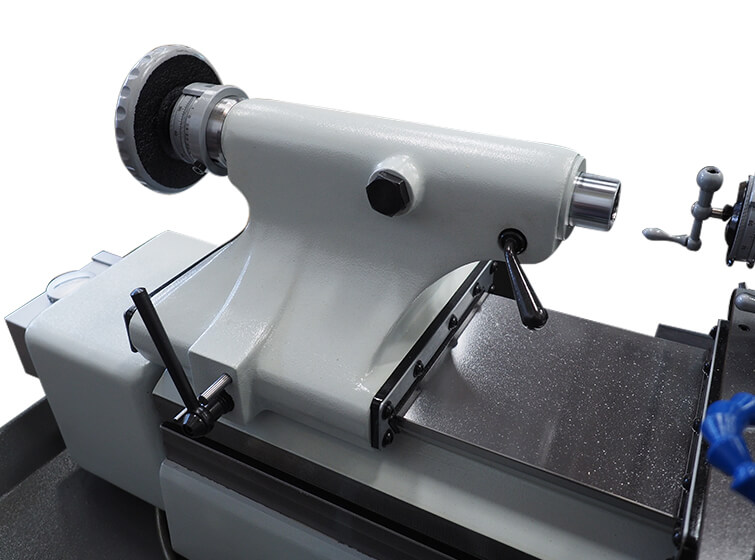

| Tailstock Spindle Diameter | Ø34.5 mm (1.358") |

| Tailstock Spindle Taper | MT. #2 |

| Tailstock Spindle Travel | 95 mm (3-3/4") |

| Coolant Pump | 1/6 HP, 220V, 3PH |

| Feed Inverter Motor | 1/2 HP |

| Range of Threads | 0.275–2.7 mm (11–108 TPI) |

| Main Motor | 3 HP, 220V, 3PH |

| Feed Motor | 110V, 70W |

| Net/Gross Weight | 1,804/2,024 lb. (820/920 kg.) |

| Machine Packing Dimension | 1,910 x 850 x 1,860 mm (75" x 33" x 73") |

All dimensions, specifications, and machine appearance are subject to change without prior notice.

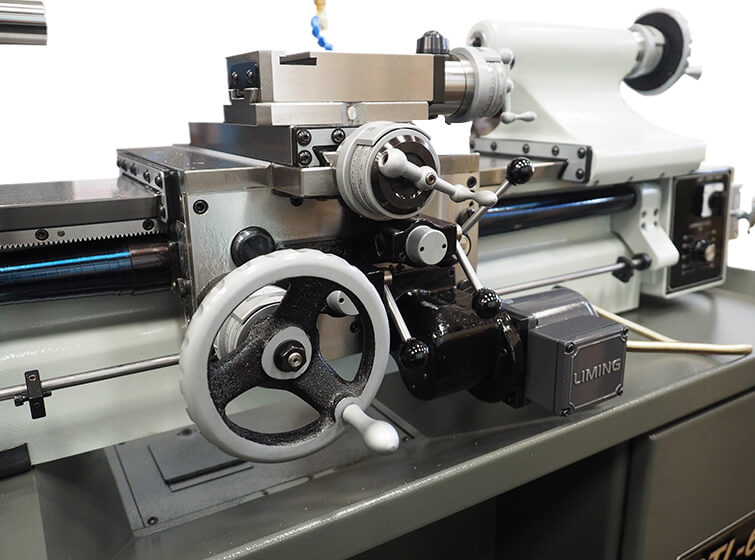

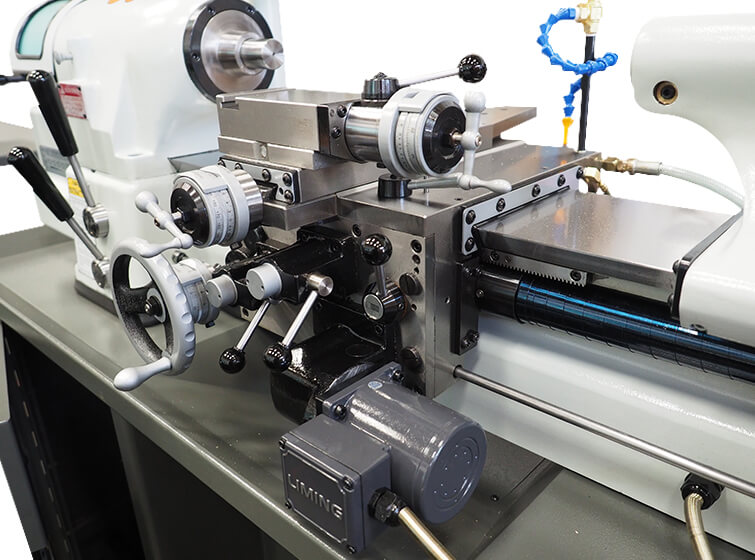

Control Panel and Operation #

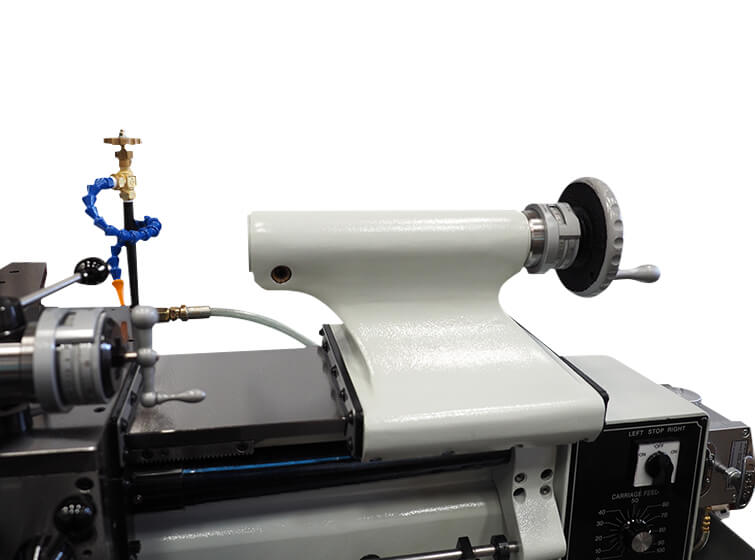

The CTL-618EVS features an electronic vari-speed system with inverter, allowing spindle speeds to be set from 50 to 4000 RPM while running. The actual RPM is displayed digitally for easy monitoring. The dual range Inch/Metric quick change gearbox streamlines threading and feed adjustments.

Installation and Maintenance #

- Leveling: The machine is equipped with six adjustable feet for precise leveling. Use a spirit level in both X and Z directions on the slideway.

- Lifting: The net weight is approximately 1050 kg (2300 lbs). Use ropes or cables rated for at least 3000 lbs, with soft cloth pads to protect the machine.

- Inspection and Cleaning: Upon arrival, inspect for shipping damage and clean all antirust liquid from exposed surfaces using a soft brush and solvent. Avoid using compressed air.

- Foundation: A solid, flat foundation of at least 300 mm (12") thickness is recommended.

- Electrical Connections: The lathe is shipped fully wired. Ensure correct motor voltage and spindle rotation direction before operation.

- Lubrication:

- Carriage: Use Mobil Vactra Oil No.2 or equivalent.

- Gearbox and Clutch: Use Automatic Transmission Fluid Mobil 200 (Esso ATF or equivalent), change every 500 hours.

- Headstock: Bearings are grease-packed for life.

Threading and Feed Systems #

- Quick Change Gearbox: Instantly select from 36 different inch and metric threads. The gearbox allows for rapid setup and precise threading.

- Automatic Thread Length Control: Adjustable stops enable accurate threading to a shoulder or blind hole without thread relief.

- Carriage and Cross Slide: Both feature dual dials (inch and metric) for operator convenience, with spring-loaded indicating rings for easy adjustment.

- Power Feed Unit: AC motor-driven, with direction and rate of feed controlled via cam switches. Settings are determined by test cuts for optimal surface finish and production rate.

Accessories and Optional Equipment #

A wide range of spindle tooling, holders, and optional equipment is available to expand the lathe’s capabilities:

Examples of Available Accessories #

- Step chucks and closers (various sizes)

- Chuck back plates, face plates, and fixture plates

- 3-jaw and 4-jaw chucks

- Lathe dogs, angle plates, and drive plates

- Expanding collets and pads

- Hydraulic, pneumatic, and diaphragm chucks

- Tool holders (single, double, triple, boring, drill, adjustable, quick-change, extension, etc.)

- Steady and follow rests

- Taper and radius turning attachments

- Rear tool holder slide assemblies

- Carriage length indicators, micrometer stops, and more

Each accessory is designed to integrate seamlessly with the CTL-618EVS, supporting a wide range of machining operations from turning and facing to threading, boring, and parting off.

Operation Manual Highlights #

The operation manual covers essential topics such as:

- Level adjustment and installation

- Lifting and handling

- Inspection, cleaning, and lubrication

- Electrical setup and safety

- Gearbox and threading operations

- Carriage, cross slide, and tailstock adjustments

- Use of optional accessories and tooling

Applications #

The CTL-618EVS is suitable for toolrooms, precision manufacturing, prototyping, and small-batch production where accuracy, repeatability, and versatility are paramount. Its robust design and comprehensive accessory support make it adaptable to a wide variety of turning tasks.

For further details, technical support, or to explore customization options, please refer to the official product page or contact the manufacturer directly.