Advanced Capabilities for Modern Toolrooms #

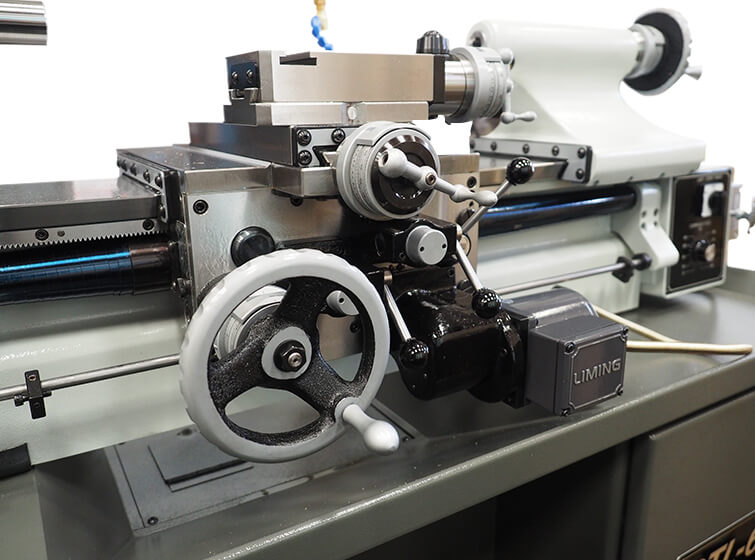

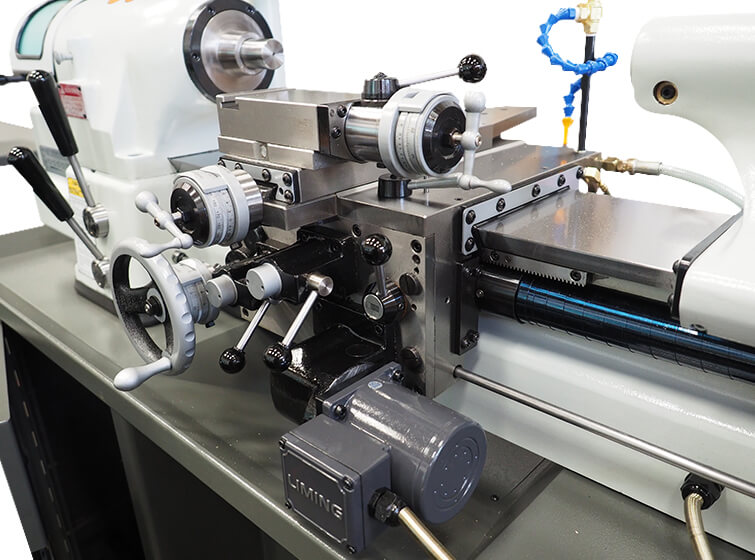

The CTL-618e toolroom lathe is engineered for high-speed, high-accuracy machining, making it an ideal choice for toolmakers and precision part manufacturers. This model stands out by replacing the traditional threading gearbox with a computer-controlled servo motor directly linked to the leadscrew. This innovation allows users to select the desired thread pitch via a touchscreen display, ensuring precise threads and eliminating the need for specialized gear sets.

Key Features #

- Digital Threading Control: The CTL-618e utilizes a microprocessor-controlled, servo-driven leadscrew, enabling instant selection of thread pitches (both metric and inch) without manual gear changes. Simply input the desired pitch on the LCD touchscreen, and the system synchronizes spindle rotation and Z-axis feed for accurate threading.

- Integrated DRO Functions: Built-in digital readout (DRO) capabilities come standard, with linear scales on X and Z axes from Mitutoyo, providing real-time feedback on spindle speed, feed rate, and tool position.

- High Precision: Guaranteed circular accuracy of 50 millionths of an inch, suitable for super high-precision work on small parts, especially those fitting in 5C collets.

- Noise and Vibration Reduction: The absence of gears in the gearbox significantly reduces operational noise and vibration during threading.

- Rapid Retract Function: Shortens processing time for pitch and module turning.

- Easy Metric/Inch Switching: Effortlessly switch between measurement systems, with accuracy up to three digits after the decimal point.

- Digital Overload Monitoring: Real-time display of electric current for easy overload detection.

Control Panel and Operation #

The CTL-618e features an intuitive LCD touchscreen interface for all major operations:

- Thread Pitch Selection: Choose thread pitch and type (right/left hand) directly on the screen.

- Spindle and Feed Monitoring: Digital display of spindle RPM and tool infeed.

- Memory Functions: Store up to 8 sets of X and Z positions for repeatable operations.

- Automatic Thread Length Control: Ensures precise thread termination, especially for blind holes or shoulders.

- Dynamic Braking: Inverter unit with discharge resistor for rapid spindle stop.

Specifications #

| Feature | Specification |

|---|---|

| Spindle Capacity (Chuck) | 150 mm (6") |

| Spindle Capacity (Expanding Collets) | 76 mm (3") |

| Spindle Capacity (Round 5C Collets) | 27 mm (1-1/16") |

| Spindle Capacity (Hexagon 5C Collets) | 22 mm (7/8") |

| Spindle Capacity (Square 5C Collets) | 19 mm (3/4") |

| Spindle Capacity (Step Chucks) | 27 ~ 152 mm (1-1/16–6") |

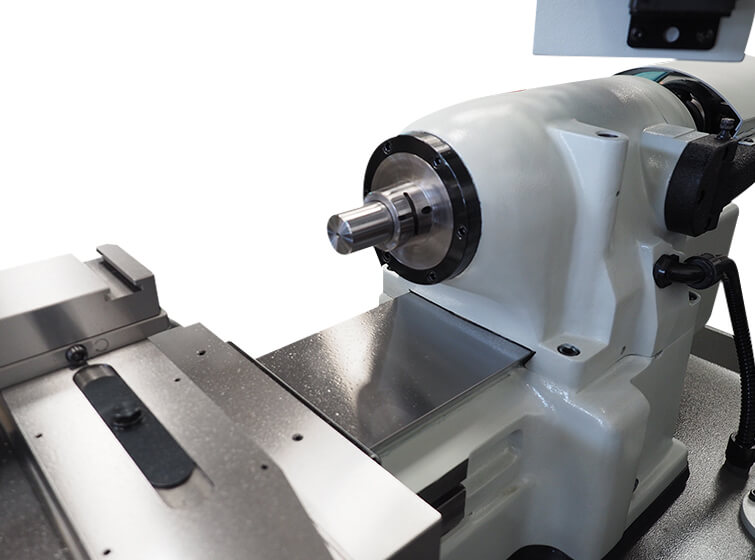

| Spindle Nose Diameter | Ø55.5 mm (Ø2.189") |

| Spindle Nose I.D/O.D | 5C (10°) / 4° Taper |

| Spindle Speeds (Variable) | 50–4,000 rpm (5C) / 50–3,000 rpm (6" 3-jaw chuck) |

| Inverter Spindle Motor | 3 HP |

| Hole Through Spindle | 31.75 mm (1-1/4") |

| Bar Stock Diameter (5C collet) | Ø27 mm (1-1/16") |

| Distance Between Centers | 457 mm (18") |

| Swing Over Bed | 280 mm (11") |

| Swing Over Carriage | 230 mm (9") |

| Swing Over Cross Slide | 152 mm (6") |

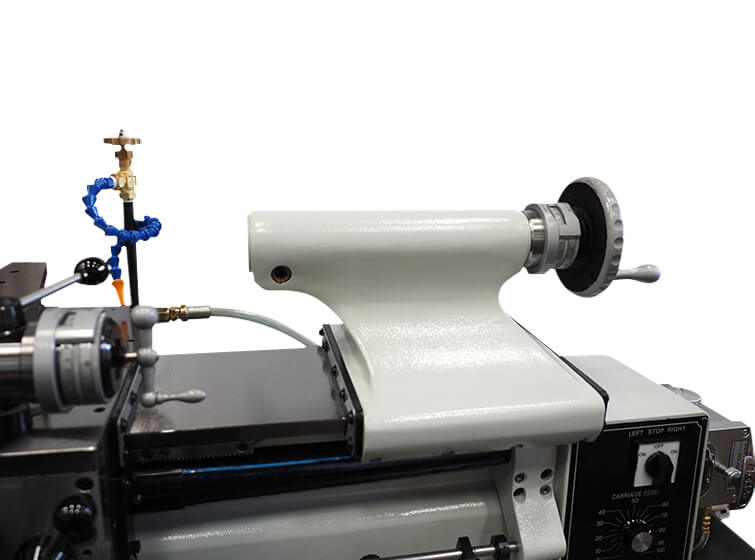

| Carriage Power Feed Range | 8–178 mm (5/16"–7") |

| Cross Slide Power Feed Range | 5–102 mm (3/16"–4") |

| Cross Slide Travel | 152 mm (6") |

| Compound Slide Travel | 76 mm (3") |

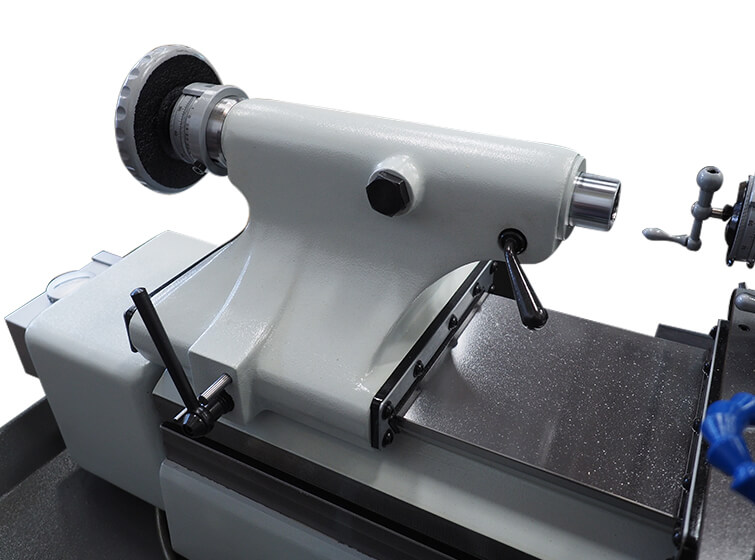

| Tailstock Spindle Diameter | Ø34.5 mm (1.358") |

| Tailstock Spindle Taper | MT. #2 |

| Tailstock Spindle Travel | 95 mm (3-3/4") |

| Coolant Pump | 1/6 HP, 220V, 3PH |

| Feed Inverter Motor | 1/2 HP |

| Range of Threads | 0.55–6.55 mm (3.175–500 TPI) |

| Main Motor | 3 HP, 220V, 3PH |

| Feed Motor | 110V, 70W |

| Net/Gross Weight | 1,760/1,980 lbs. (800/900 kg) |

| Machine Packing Dimension | 2,000 x 850 x 1,900 mm (79" x 33" x 75") |

Spindle Tooling and Accessories #

A wide range of spindle tooling, holders, and optional equipment is available for the CTL-618e, supporting diverse machining needs:

- Step Chucks and Closers: For holding work up to 162 mm in diameter, available in regular and extra depth capacities.

- Threaded Positive Stops: Adjustable stops for precise part length control.

- Universal Collet Stop: Converts 5C collets for solid or spring ejector stop use.

- Plug Chucks, Fixture Plates, Face Plates: For custom workholding and special setups.

- Chucks: 3-jaw, 4-jaw, fine turning, hydraulic, pneumatic, and diaphragm chucks.

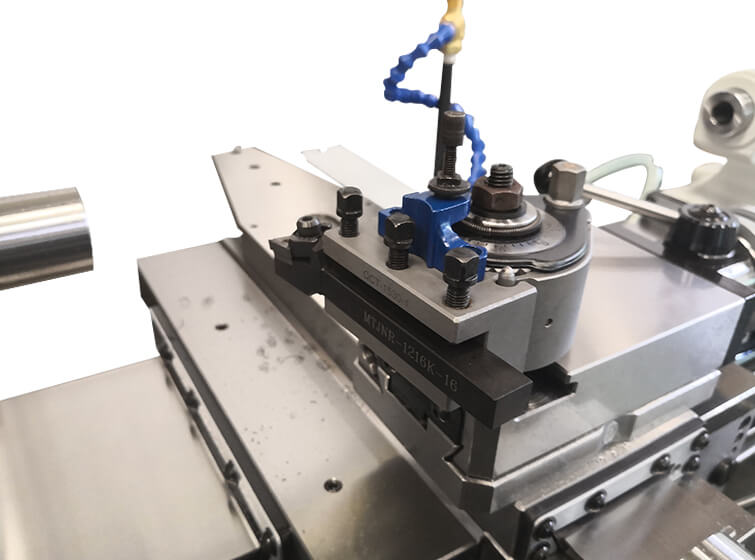

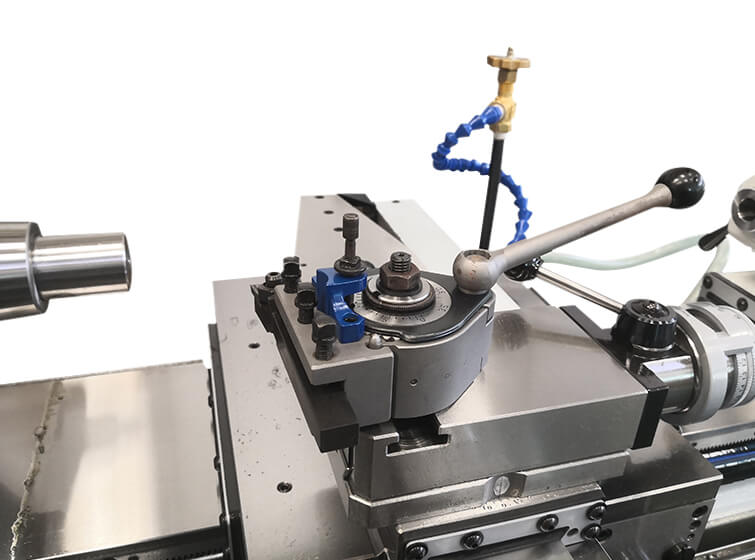

- Tooling Holders: Single, double, triple, boring, drill, adjustable, quick-change, and extension holders for various operations.

- Optional Equipment: Includes steady and follow rests, six-station turret, taper and radius turning attachments, rear tool holder slide, bed length indicator, automatic indexing turret, chip and coolant shield, and more.

Maintenance and Setup #

- Foundation and Leveling: Six adjustable feet ensure stable installation and long-term accuracy.

- Electrical Connections: Shipped pre-wired; simple connection to power source and ground.

- Lubrication: Carriage, gearbox, and headstock require regular lubrication with specified oils.

- Collet Closer: Easy removal, replacement, and adjustment for optimal workholding.

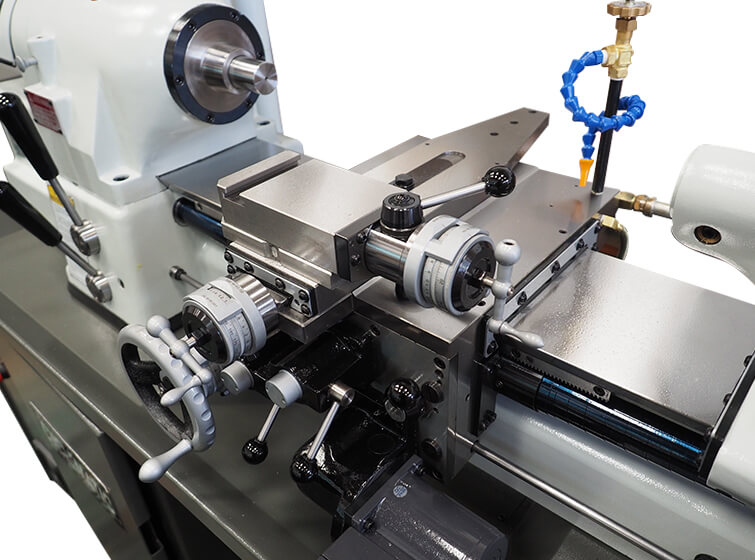

- Carriage and Cross Slide: Dual dials for inch/metric, spring-loaded indicating rings, and quick-action compound slide for efficient operation.

- Tailstock: Preloaded ball bearings, fine feed, and dual dial graduations for precise support.

Image Gallery #

Additional Resources #

For further information on spindle tooling, holders, and optional equipment, please refer to the detailed product pages or contact the manufacturer directly.