Overview of the CTL-27EVS High Precision Toolmaker Lathe #

The CTL-27EVS is engineered for toolmakers and precision machinists who require exceptional accuracy and versatility when working with small-diameter parts. This toolroom lathe features a variable speed spindle, robust construction, and a comprehensive range of spindle tooling and accessories to support a wide variety of machining operations.

Key Features #

- Variable Speed Spindle: Infinitely adjustable from 50 to 4000 RPM, allowing optimal cutting speeds for various materials and operations.

- 5C Collet System: Accommodates a wide range of workpiece shapes and sizes, enhancing flexibility for toolmaking and small-part production.

- Compound Slide (X-Z Axis): Enables precise two-axis movement for turning, facing, and boring tasks.

- High/Low Speed Quick Change Lever: Facilitates rapid speed adjustments for increased productivity.

- Robust Construction: Saddle slideways are coated with Turcite-B for superior wear resistance, while cross slideways feature hardened and ground tool steel inserts for smooth, accurate movement.

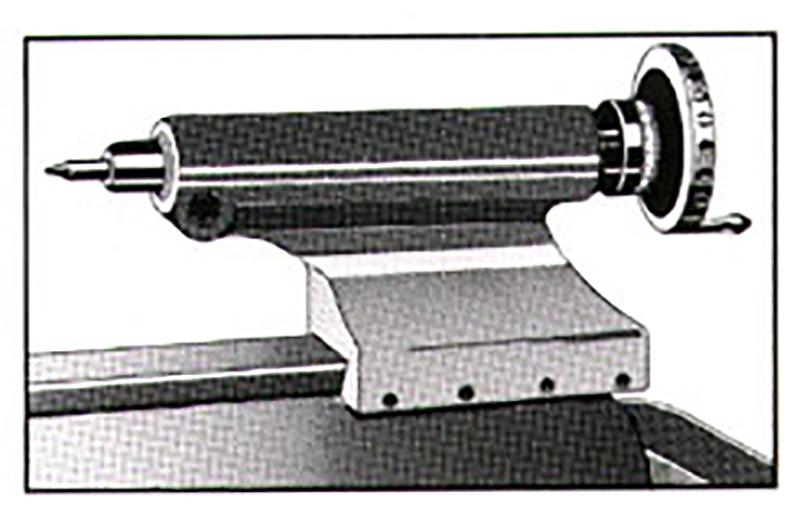

- Screw Feed Tailstock: Standard on the CTL-27EVS, providing reliable support for center work.

Technical Specifications #

| Specification | Value |

|---|---|

| Spindle Capacity (with Chuck) | 150 mm (6") |

| Spindle Capacity (with Expanding Collets) | 76 mm (3") |

| Spindle Capacity (with Round 5C Collets) | 27 mm (1-1/16") |

| Spindle Capacity (with Hexagon 5C Collets) | 22 mm (7/8") |

| Spindle Capacity (with Square 5C Collets) | 19 mm (3/4") |

| Spindle Capacity (with Step Chucks) | 27 ~ 152 mm (1-1/16–6") |

| Spindle Nose Diameter | Ø55.5 mm (Ø2.189") |

| Spindle Nose I.D/O.D | 5C (10°) / 4° Taper |

| Spindle Speeds (Variable) | 50–4000 RPM |

| Inverter Spindle Motor | 3 HP |

| Hole Through Spindle | 31.75 mm (1-1/4") |

| Bar Stock Diameter (5C collet) | Ø27 mm (Ø1-1/16") |

| Distance Between Centers | 380 mm (18") |

| Swing Over Bed | 229 mm (9") |

| Compound Slide Travel | X: 114 mm (4.488") / Y: 140 mm (5.512") |

| Tailstock Spindle Diameter | 34.5 mm (1.358") |

| Tailstock Spindle Taper | MT. #2 |

| Tailstock Spindle Travel | 95 mm (3-3/4") |

| Coolant Pump | 1/8 HP, 220V, 3PH |

| Main Motor | 3 HP, 220V, 3PH |

| Net/Gross Weight | 990/1,364 lb. (450/620 kg) |

| Machine Packing Dimension | 1,910 × 850 × 1,790 mm (74" × 34" × 74") |

All dimensions, specifications, and machine appearance are subject to change without prior notice.

Construction and Operation Highlights #

- Turcite-B Coated Slideways: Both the saddle and cross slideways are engineered for maximum wear resistance and smooth, accurate movement.

- Precision Ball Bearings: The headstock spindle is mounted on preloaded ball bearings, grease-packed for life, ensuring long-term accuracy and minimal maintenance.

- Dynamic Spindle Braking: The inverter unit and discharge resistor provide efficient dynamic braking for rapid spindle stops.

- Coolant Facilities: Integrated coolant pump with selectable continuous or automatic operation, supporting high-speed machining and chip management.

Installation, Setup, and Maintenance #

- Lifting and Handling: The machine weighs approximately 540 kg (990 lbs). Use strong ropes or cables and soft cloth pads to protect machine edges during lifting.

- Foundation and Leveling: A solid foundation (minimum 30 mm thickness) and proper leveling using the six adjustable feet are essential for maintaining machining accuracy.

- Wiring: Ensure correct power supply connection and spindle rotation direction before operation. Interchange any two lead lines if spindle rotation is incorrect.

- Lubrication: Use high-quality lubricating oil and check levels regularly. The headstock bearings require no additional lubrication.

- Belt Adjustment: Regularly check and adjust belt tension for optimal performance.

Collet Closer Operation #

- Removal and Replacement: Remove the collet closer when using jaw chucks, face plates, or other fixtures. Clean and lightly oil all surfaces before reinstallation.

- Adjustment: Follow the step-by-step procedure to set the correct gripping pressure for collets or step chucks, ensuring secure and accurate workholding.

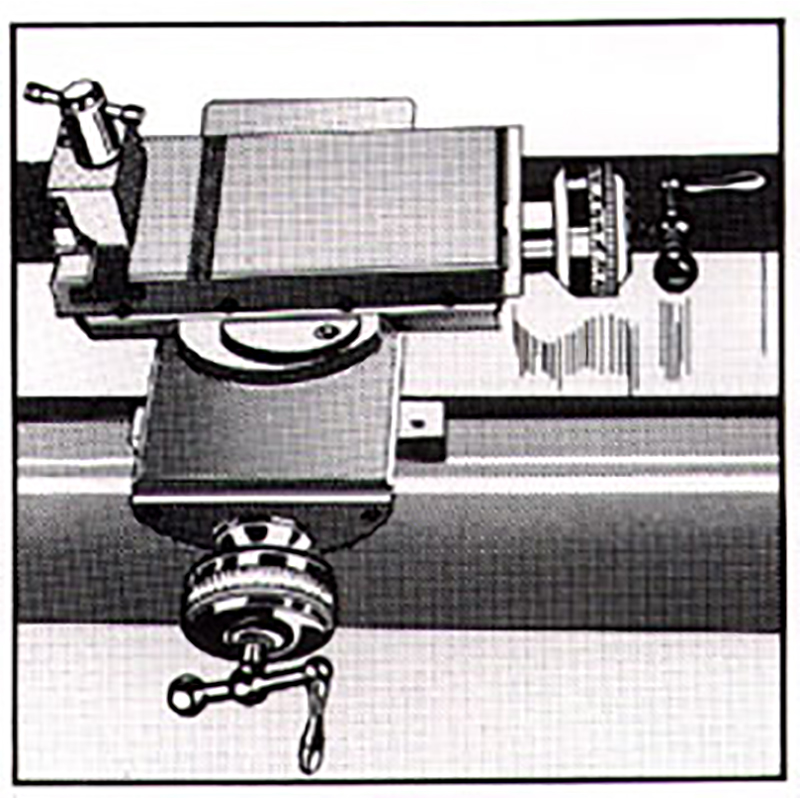

Compound Slide and Tailstock #

- Compound Slide: Large-diameter, hardened feed screws with preloaded ball bearings and 2" dials provide direct, adjustable readings in thousandths for precision turning, facing, and boring.

- Tailstock: Mounts directly to the bed ways, supporting center work with fine feed and dual inch/metric graduations for operator convenience.

Optional Accessories and Tooling #

A comprehensive selection of spindle tooling, holders, and optional equipment is available to expand the capabilities of the CTL-27EVS. These include:

- Step Chucks and Closers: For holding workpieces up to 162 mm in diameter.

- Threaded Positive Stops and Universal Collet Stops: For precise part length control.

- Plug Chucks, Fixture Plates, and Face Plates: For custom workholding solutions.

- Chucks (3-jaw, 4-jaw, fine turning, hydraulic, pneumatic, diaphragm): For various gripping needs.

- Tool Holders: Single, double, triple, boring, drill, adjustable, quick-change, and extension holders for diverse tooling setups.

- Special Attachments: Taper turning, radius turning, rear tool holder slide, automatic indexing turret, steady and follow rests, chip and coolant shields, and more.

Applications #

The CTL-27EVS is ideal for:

- Precision toolmaking

- Machining small-diameter shafts, bushings, and custom components

- Prototyping and small-batch production

- Educational and research environments requiring high-accuracy manual lathes

Contact and Customization #

For further information, custom orders, or to discuss specific application requirements, please contact us. Customized CNC toolroom lathes are also available upon request.