Precision Engineering of the CTL-20 Toolroom Lathe #

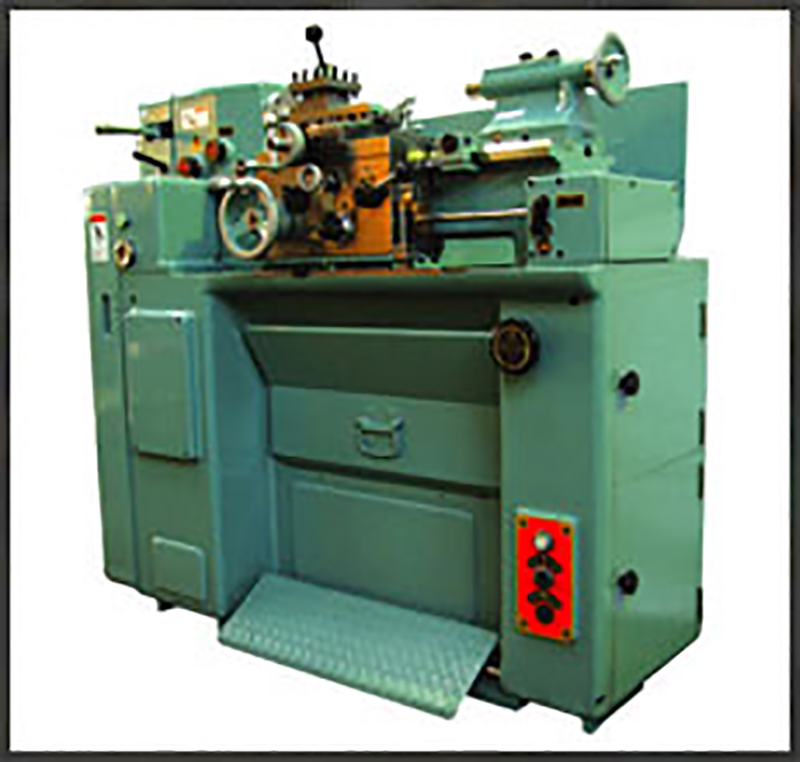

The CTL-20 Toolroom Lathe is engineered to deliver exceptional accuracy and reliability for precision turning applications. Its design incorporates advanced spindle technology, robust construction, and user-focused features, making it a valuable asset in any toolroom or workshop.

Key Features #

-

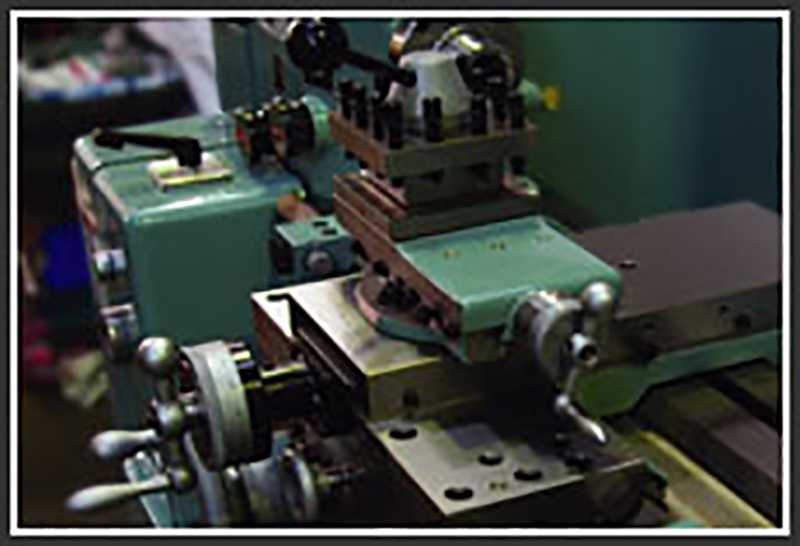

Spindle System: The spindle utilizes a copper conical bearing with oil film lubrication, minimizing heat deformation and ensuring smooth, high-quality finish cutting. The spindle is precisely ground with a taper hole and supported at three points to maintain high accuracy during operation.

-

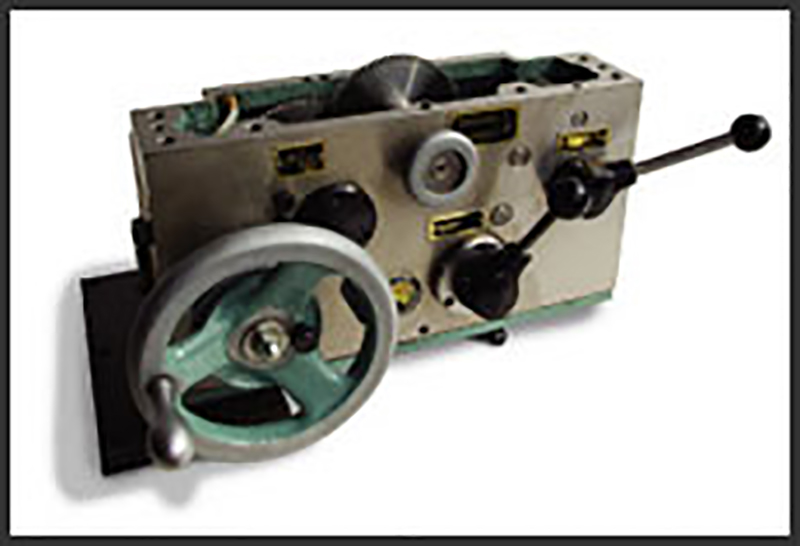

Apron and Feed Controls: Integrated automatic controls for both longitudinal and cross feeds, including forward and reverse feed options. The automatic feed system allows for adjustable travel distance, enhancing operational safety. Both manual and automatic lubrication systems are provided for the cross slide and bed way.

-

Machine Bed and Construction: The bed is cast, heat-treated, and precision ground to extend machine life. The rigid casting absorbs vibration and provides high strength, supporting stable and accurate machining.

-

Tailstock and Safety: Features a user-friendly tailstock (M.T. No2) and an emergency foot-operated braking system for enhanced safety during operation.

Standard Equipment #

- Turning indicator (35 & 36/per set)

- 22-piece changeable gear set

- Tool box

- Four foot stands

- One male center

Optional Accessories #

- Steady rest

- Follow rest

- Four-setting longitudinal-feed stop device

- Coolant device

- Work light

- 3-jaw or 4-jaw chuck

- Mounting plate

- MT2 live center

Technical Specifications #

| Specification | Unit | CTL-20 |

|---|---|---|

| Capacity | ||

| Max. Swing | mm | 240 |

| Max. Cutting O.D. | mm | 140 |

| Distance Between Centers | mm | 390 |

| Collet | ||

| Collet Type | mm | EDA-8 |

| Bore (I.D.) | mm | 20 |

| Square | mm | 13 |

| Hexagon | mm | 16 |

| O.D. | mm | 25 |

| Spindle | ||

| Hole Through Spindle | mm | 22 |

| Spindle Speed Variation | speed | 10 |

| High Speed (H) | mm | 360, 1100, 1600, 2000, 2600 |

| Low Speed (L) | mm | 180, 550, 800, 1000, 1300 |

| Cross Slide | ||

| Removal Speed Variation | speed | 6 |

| Feed (transverse 1/2) | mm/rev | 0.02, 0.03, 0.05, 0.08, 0.12, 0.20 |

| Thread Range | ||

| Range | mm, tooth/inch | 0.2~0.5, 40~7 |

| Lead of Lead Screw | mm | 6 |

| Tailstock | ||

| Tailstock | mm | 36 |

| Tailstock Spindle | mm | MT No.2 |

| Tailstock Travel | mm | 130 |

| Bed | ||

| Length | mm | 1000 |

| Width | mm | 230 |

| Main Motor | kw | 220V-2.2/1, 1-4/8P |

| Machine Dimension | mm | 1310x670x1150 |

| Machine Weight | kg | 1000 |

All dimensions, specifications, and machine appearance are subject to change without prior notice.

For more information or to discuss customized CNC toolroom lathe solutions, please contact us.