Advanced Capabilities and Design of the CT-1118CNC CNC Toolroom Lathe #

The CT-1118CNC CNC Toolroom Lathe is engineered to deliver exceptional precision, flexibility, and efficiency for demanding machining environments. Designed as an upgrade from the CTL-618EVS manual lathe, this model integrates robust mechanical construction with advanced CNC control, making it suitable for aerospace, automotive, electronics, and other high-precision industries.

Key Features #

- Guaranteed circular accuracy to 50 millionths of an inch

- Fanuc 0i mate-TF controller (standard), with options for other controllers

- 3 HP motor (5 HP optional) paired with a Yaskawa current vector inverter for enhanced low-end torque

- Spindle mounted on high-precision preloaded angular contact ball bearings

- Precision ballscrews on X and Z axes, with direct AC servo motor coupling to minimize backlash

- Protection guard on Z-axis ballscrew

- Fast lever collet chucking and power collet closer

- Optional gang tooling for increased productivity

- Wide range of accessories to expand versatility

Dual Machining Styles: Center Turning & Gang Turning #

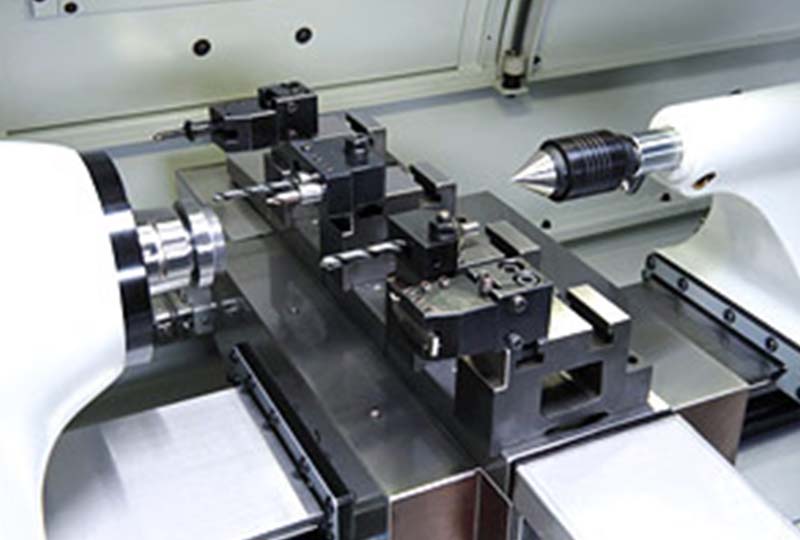

The CT-1118CNC stands out for its ability to switch between traditional center turning and innovative gang turning. The machine retains the durability and classic design of its predecessor while introducing a tool plate system that allows users to remove the compound tool post and install a T-slot gang tool slide. This flexibility enables:

- Easy transition between traditional and gang tooling setups

- Support for both shaft work (with tailstock and lathe center) and high-volume, multi-tool operations

- Compatibility with a comprehensive lineup of CYCLEMATIC gang tool holders

Gang Tooling for Enhanced Productivity #

Gang tooling on the CT-1118CNC simplifies setups for jobs requiring multiple tool changes, making it ideal for higher-volume production of precision parts. The system supports a variety of tool holders and configurations, allowing users to tailor the machine to specific production needs.

Technical Specifications #

| Parameter | Value |

|---|---|

| Maximum Swing | 380 mm |

| Maximum Turning Diameter | Ø150 mm (6") |

| Distance Between Centers | 457 mm |

| Bar Stock Diameter (5C collet) | Ø27 mm (1-1/16") |

| Hole Through Spindle | Ø31.75 mm (1-1/4") |

| CNC Controller | FANUC (Standard) |

| Spindle Speeds (Variable) | 50~4000 RPM (3HP) / 50~6000 RPM (5HP) |

| Spindle Nose I.D./O.D. | 5C (10°) / 4° Taper |

| Quick-Action Compound Slide Travel | 2.5 mm (0.1") |

| Chuck Diameter | Ø150 mm (6") |

| Maximum X-axis Travel | 220 mm (8.661") |

| Maximum Z-axis Travel | 340 mm (13.386") |

| Rapid Traverse | 20 m/min |

| Inverter Spindle Motor | 3 HP / 5HP (Option) |

| X, Z-axis Servo Motor | X: s2 / Z: s2 |

| Coolant Pump | 1/4 HP |

| Tailstock Spindle Taper | MT No.2 |

| Tailstock Spindle Travel | 95 mm |

| Net/Gross Weight | 2,530/2,750 lb. (1,100/1,200 kg) |

| Machine Packing Dimension | 2,300 x 1,200 x 1,970 mm (91" x 47" x 78") |

Specifications and appearance are subject to change without notice.

Construction Highlights #

- Massive Saddle: Slideways are coated with Turcite-B for wear resistance; cross slideways feature hardened and ground tool steel inserts for smooth, accurate movement.

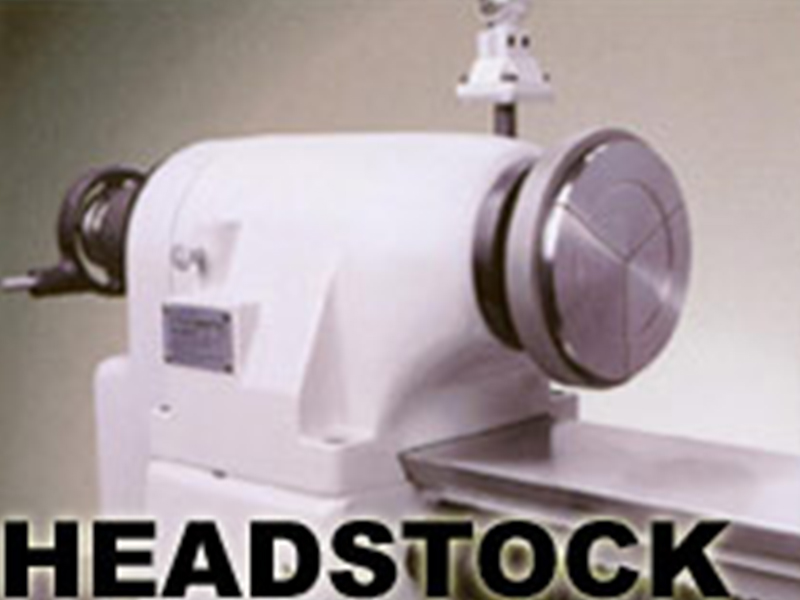

- Headstock: One-piece enclosed design with high-precision preloaded ball bearing spindle for rigidity and sustained accuracy. The collet seats directly in the spindle, eliminating the need for sleeves or adapters.

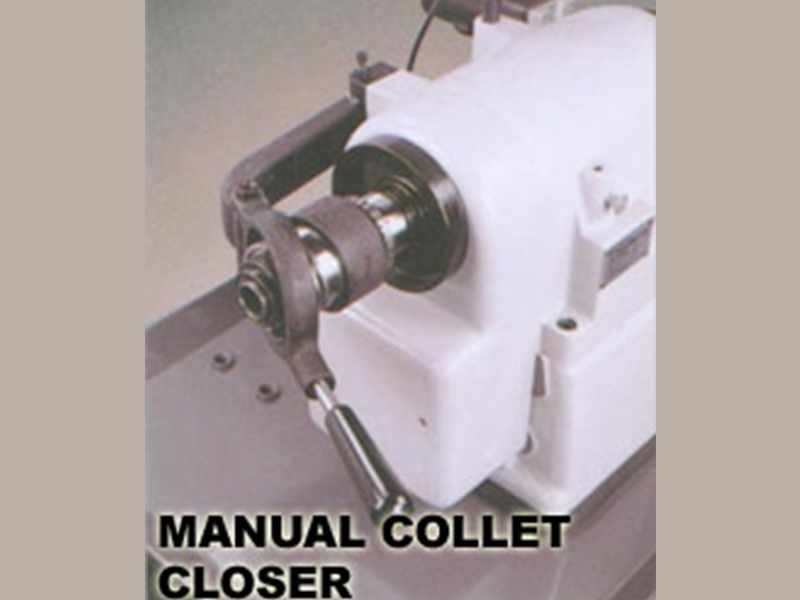

- Collet Closer: Fast lever collet closer for quick chucking, with instant tension adjustment. Optionally, an air-operated power collet closer is available for automatic chucking.

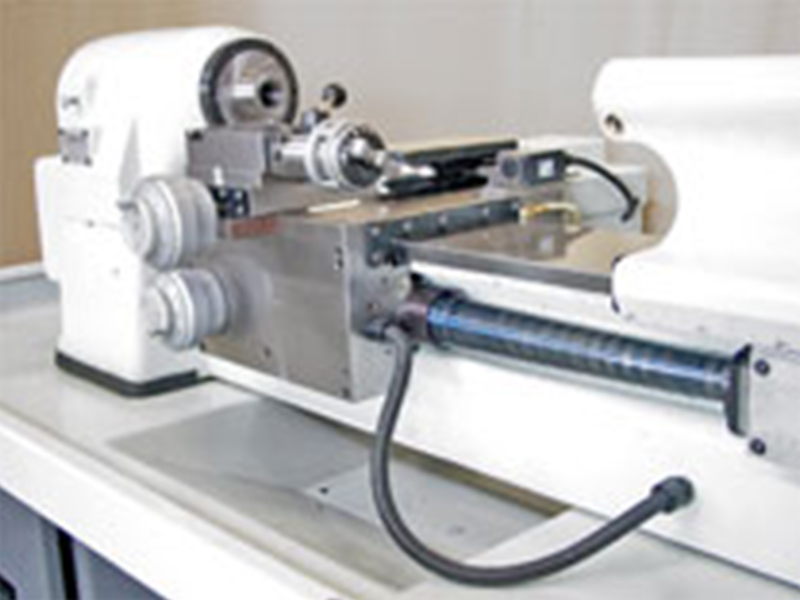

- Tailstock: Full bearing support, 95mm travel, dual inch/metric graduations, and automatic tool discharge for MT#2 taper tools.

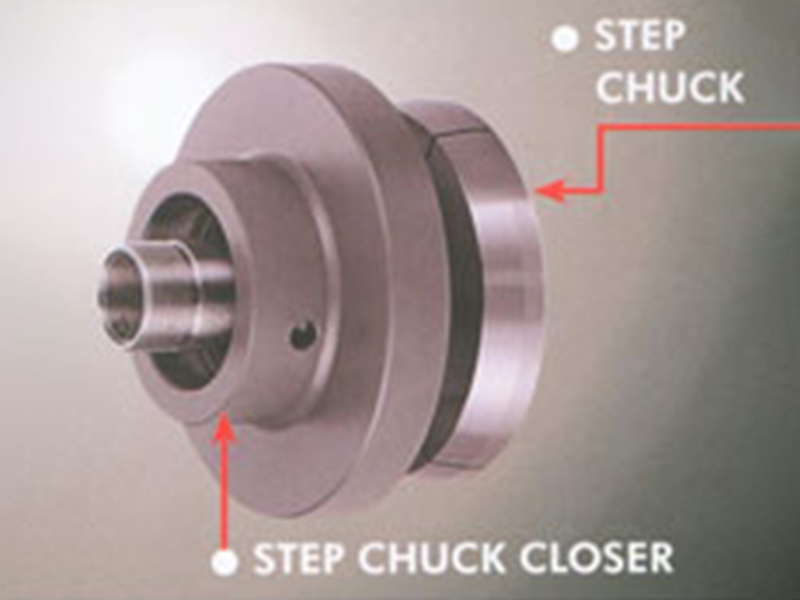

- Step Chucks: Securely hold work up to 6" in diameter, with closers designed for direct spindle fit and optimal gripping power.

Tooling and Accessories #

A comprehensive selection of spindle tooling, tool holders, and optional equipment is available to further enhance the CT-1118CNC’s capabilities. These include:

- Step chucks and closers (various sizes and depths)

- Threaded positive stops, universal collet stops

- Plug chucks, fixture plates, face plates

- Angle plates, headstock centers, drive plates, driving dogs

- Chuck mounting plates, fine turning chucks, expanding collets

- Hydraulic, pneumatic, and diaphragm chucks

- Single, double, triple, and boring tool holders

- Gang tool blocks (408mm, 96mm, 48mm)

- Drill holders, tap holders, knurling holders, quick-change holders

- Tool setting gages, carriage length indicators, steady and follow rests

- Six-station turret, taper and radius turning attachments, rear tool holder slides, vertical cut-off slides, compound slides, tailstocks, chip and coolant shields, and more

Machining Samples #

Operational Guidance #

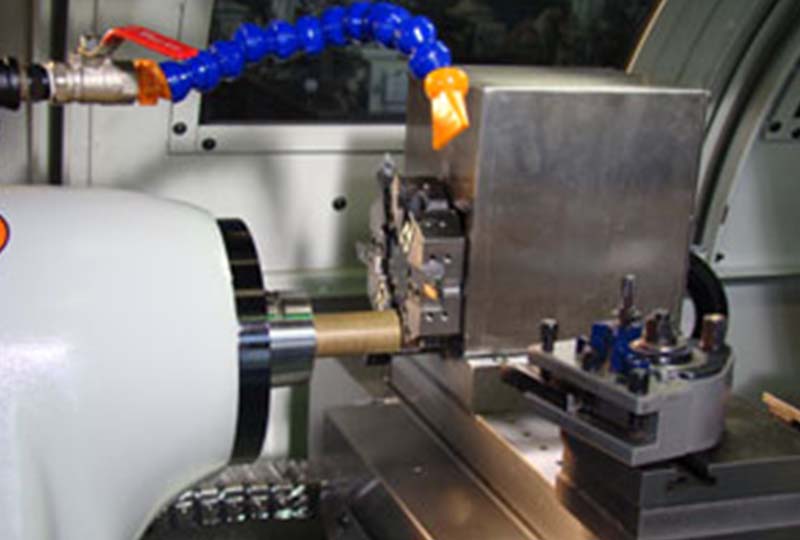

The CT-1118CNC is designed for straightforward installation, operation, and maintenance. Key operational highlights include:

- Leveling and Setup: Use pads under six points, adjust with set screws and pin wrenches, and ensure all points contact the ground.

- Electrical Connections: Machine is shipped fully wired; connect to power source and verify spindle rotation direction.

- Lubrication: Use high-quality lubricants (e.g., Mobil Vactra Oil No.2) for the oil reservoir and monthly grease for ballscrews.

- Collet Closer: Procedures for removal, replacement, and adjustment are provided for both manual and air-operated systems.

- Coolant System: Maintain coolant levels to protect the pump; adjust flow as needed.

- Tailstock and Locks: Tailstock features fine feed, dual graduations, and secure locking mechanisms.

- Control Panel Functions: Includes power, cycle start, feed hold, emergency stop, jog, rapid traverse, spindle controls, coolant controls, and more, with clear indicator lights for machine status and alarms.

Contact and Customization #

In addition to standard models, customized orders for CNC toolroom lathes are welcome. For further details or to discuss specific requirements, please contact CYCLEMATIC.