Comprehensive Overview of Toolroom Lathes and Accessories

Table of Contents

Precision Machining Solutions: Toolroom Lathes and Accessories #

Cyclematic offers a diverse portfolio of toolroom lathes and related equipment, catering to a wide range of machining needs. The product lineup includes CNC toolroom lathes, manual toolroom lathes, and a variety of optional accessories, all engineered for high accuracy, durability, and operational efficiency.

CNC Toolroom Lathes #

CNC toolroom lathes integrate multiple cutting operations into a programmable controller, enabling automated machining with minimal human intervention. These machines are ideal for complex, multi-step processes requiring consistent precision.

- CT-1118CNC: This CNC lathe is an advanced version of the CTL-618EVS manual toolroom lathe, maintaining the original’s durability and design while incorporating servo motors and CNC controls for automated operation.

- CJ-27CNC: Features dovetail bed ways on both X and Z axes for maximum stability, making it suitable for deep turning. The gang tool block accelerates tool changes and ensures high accuracy.

Manual Toolroom Lathes #

Manual toolroom lathes, also referred to as rotating bed lathes, are designed for fixed workpiece machining with a rotating spindle. These machines are suitable for a variety of turning, facing, and boring operations.

CNC Digital Lathe | CTL-618e

CNC Digital Lathe | CTL-618e

CTL-618EVS High Precision Conventional Lathe

CTL-618EVS High Precision Conventional Lathe

CTL-27EVS High Precision Toolmaker Lathe

CTL-27EVS High Precision Toolmaker Lathe

CP-27EVS Model Variable Speed Finishing Lathe

CP-27EVS Model Variable Speed Finishing Lathe

Tool Room Lathe Machine | CTL-20

Tool Room Lathe Machine | CTL-20

- CTL-618e: Equipped with digital threading control, replacing the traditional threading gearbox for enhanced precision.

- CTL-618EVS: Features hardened and ground alloy bed ways for wear resistance, with angular guide ways that facilitate chip removal.

- CTL-27EVS: The compound slide rest is adaptable for screw feed precision turning, facing, and boring.

- CP-27EVS: Designed for high-speed, high-accuracy finishing, with a focus on spindle tooling and tool holders.

- CTL-20: Specialized for machining small and precision parts, as well as achieving fine surface finishes.

Optional Accessories #

A comprehensive range of accessories is available to enhance the performance and versatility of Cyclematic lathes. These include spindle tooling, various types of tooling holders, and additional optional equipment.

Spindle Tooling | Toolroom Lathe Accessory

Spindle Tooling | Toolroom Lathe Accessory

Tooling Holders | Optional Accessories of Lathe Machine

Tooling Holders | Optional Accessories of Lathe Machine

Optional Devices of Toolroom Lathe Machine

Optional Devices of Toolroom Lathe Machine

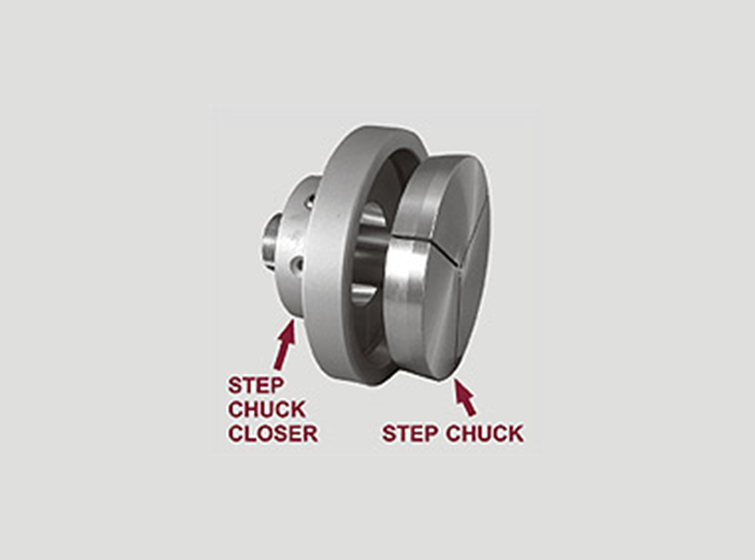

- Spindle Tooling: Designed for high-speed, high-accuracy manual lathes, these accessories support a variety of machining tasks.

- Tooling Holder: Available in single, double, triple, and boring types, these holders are manufactured for quality and reliability.

- Optional Equipment: Additional devices to further customize and optimize lathe operations.

Customization and Contact #

Cyclematic welcomes customized orders for CNC toolroom lathes, ensuring that specific requirements and unique machining challenges can be addressed. For further information or to discuss tailored solutions, please contact us.

Contact Information:

- Tel: +886-4-2562-5393, +886-4-2562-6509

- Fax: +886-4-25620298

- E-mail: cymatic@ms23.hinet.net

- Address: No. 20, Lane 50, Ming Shen Rd., Shen Kang Dist., Taichung 429, Taiwan

CNC Toolroom Lathe | CT-1118CNC

CNC Toolroom Lathe | CT-1118CNC Mini CNC Tool Room Lathe Machine | CJ-27CNC

Mini CNC Tool Room Lathe Machine | CJ-27CNC